Our Thermal Cutting class provides solutions and equipment to the metal working industry to cover a full range of cutting challenges and operations. Our oxyfuel, plasma and laser cutting systems are designed to enable our customers to better achieve their ambitions with high productivity, flexibility and quality products. Therefore, we are teaming-up with customers and partners to develop and test cutting-edge and high-quality technology under real-life conditions. In this way our customers worldwide benefit from best solutions when it comes to our machines, software and service.

Monday to Saturday

Cutting Systems

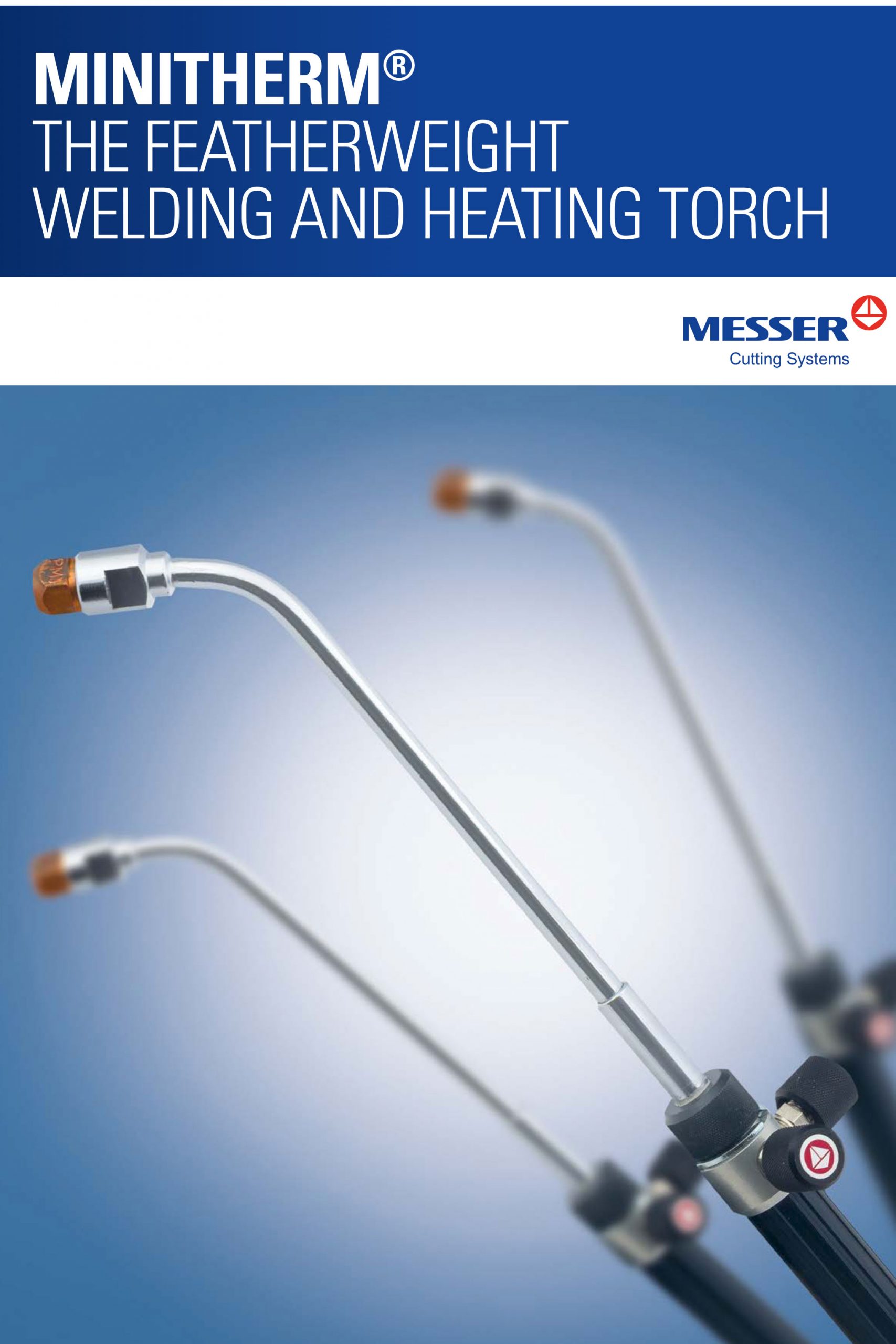

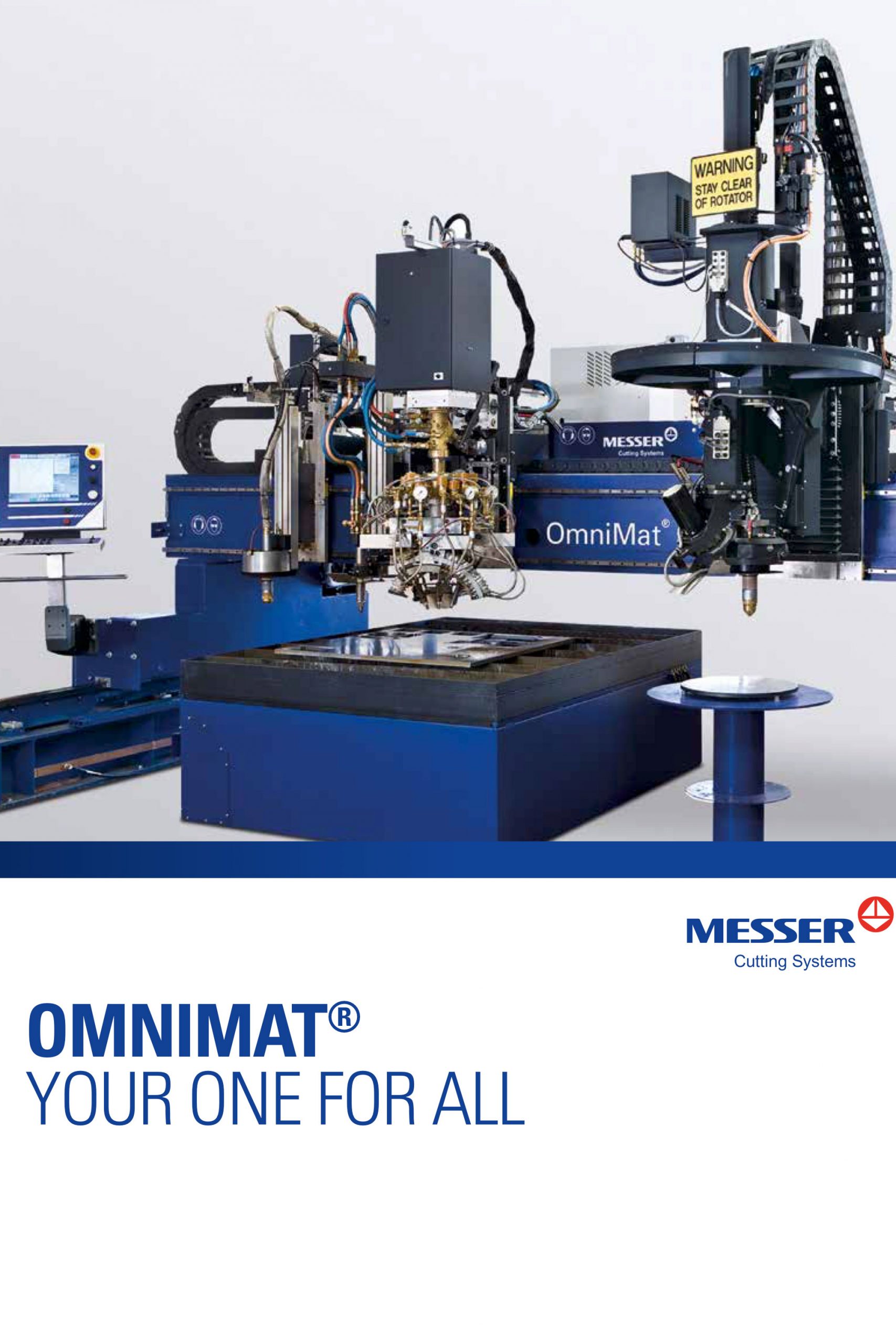

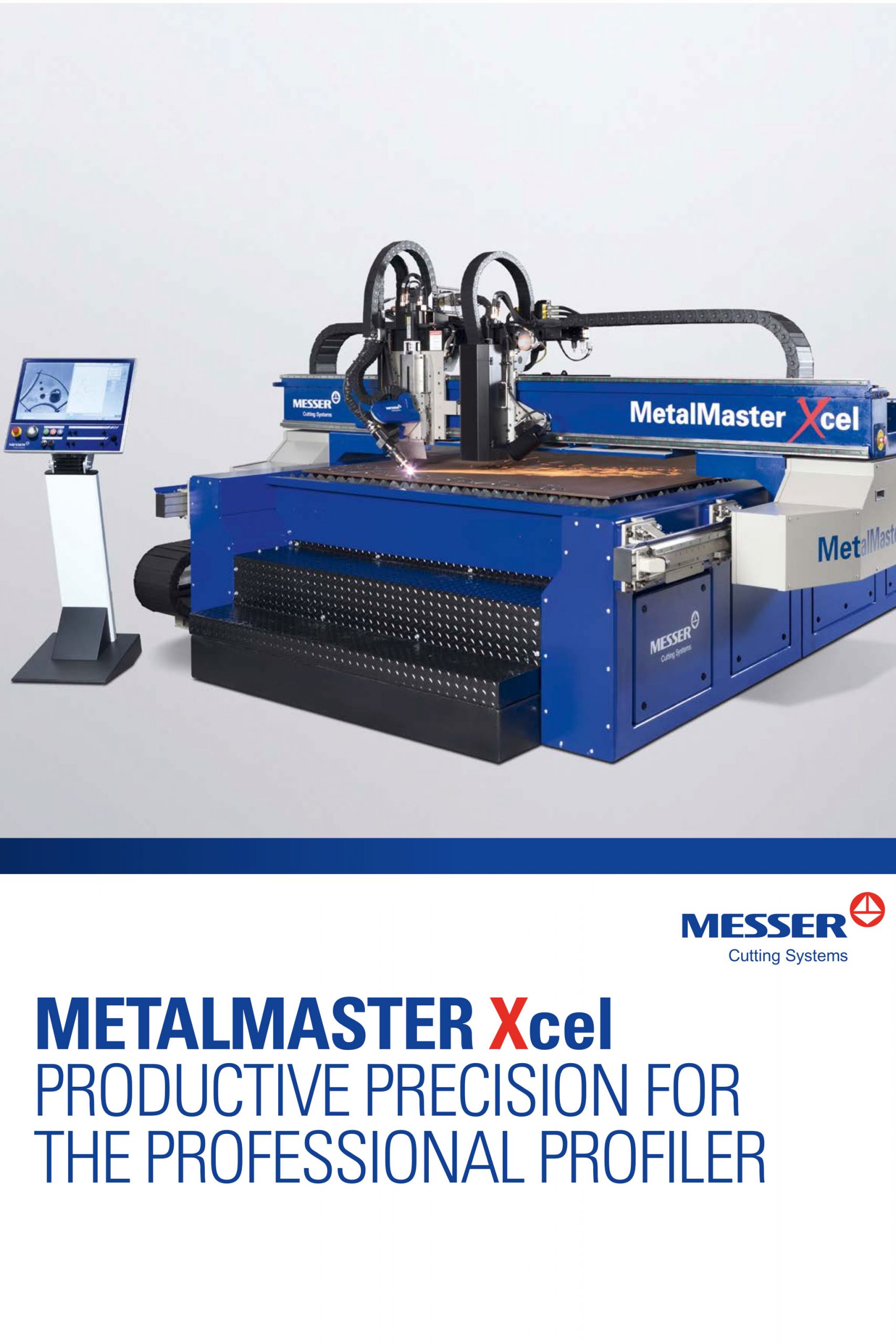

Oxyfuel Cutting Technology: Machine flame cutting ensures reliable hole-piercing, good cutting quality and allows the production of components to their finished sizes without the need for further processing. For weld seam preparations V, Y and K cuts can be produced and could be maintained for plate thickness of 3 mm – 2800 mm. Bevel cutting and straight cutting technologies could be offered as turnkey solutions to cover manufacturing challenges. The technology is available in automated systems and handheld equipment to satisfy all oxyfuel cutting requests. The key features of our Oxyfuel Cutting Technology are high cut quality, smooth vertical cutting surface and metallurgical perfect surfaces (oxidized).

Plasma Cutting Technology: Plasma cutting was originally developed for the thermal cutting of materials which were unsuitable for flame cutting, such as high alloy steels or Aluminum. Today, the process is also used for the economical cutting of thin, low alloyed steels and could be maintained for plate thickness of 0.8 mm – 160 mm. Bevel cutting and straight cutting technologies could be offered as turnkey solutions to cover manufacturing challenges. The key features of our Plasma Cutting Technology are high cutting quality, smooth cutting surface, metallurgical perfect surfaces for welding, medium heat input, excellent cutting speed and low hardening on cutting surfaces.

Laser Cutting Technology: Our laser cutting technology is used in the most diverse areas, specifically wherever high accuracy for the component geometry and the cut edge is required. . Due to the small focus spot, laser cutting is known for its high accuracy. Sublime cutting, oxygen (flame) cutting and fusion cutting are the available options for plate thickness of 1 mm – 25 mm. Bevel cutting and straight cutting technologies could be offered as turnkey solutions to cover manufacturing challenges. The technology is available in automated systems and handheld equipment to satisfy all oxyfuel cutting requests. The key features of our Oxyfuel Cutting Technology are very high-power density, high cut quality, metallurgical perfect or blank surfaces, low heat input and harding with the area of the heat affected-zone (HAZ).

Our global partners offer versatile products to our respected clients to achieve the balance between efficiency, performance and feasibility simultaneously for every operation. In addition, we offer turnkey Cutting system solutions for shipbuilding, appliances, oil and gas, transformers, heavy machinery, steel mills and associated manufacturing industries. Furthermore, we offer a machining center with the drilling, boring, counter sinking and tapping alternatives as an optional accessory for selected systems, upon request.