Our Component Testing class provides solutions and equipment to inspect the quality of components such as automotive parts and the associated elements, namely, power train and combustion engine, driving train, undercarriage, suspension system, steering, interior and exterior body parts; fasteners and connectors, namely, pegs and cotter pins, nuts and bolts, fittings, clamping rings and springs, and hollow bolts; and process control and manufacturing of powder metals, namely, carbide tools and cutting inserts, FE sintered parts, metal injection molding parts, magnets, coins, microstructure of complex mass-produced components and medical supplies an equipment.

Monday to Saturday

COMPONENT TESTING

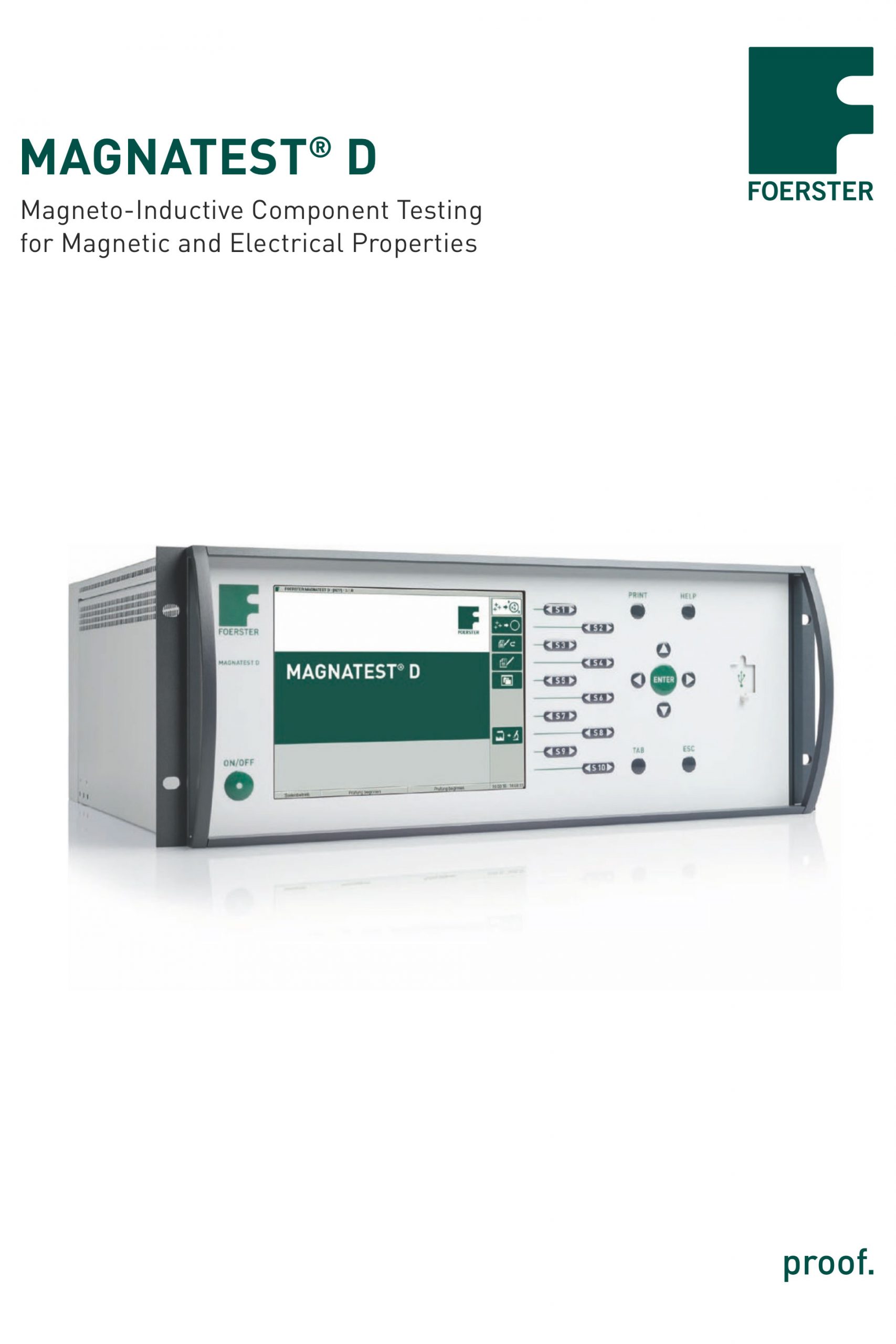

Eddy Current and Magneto Induction: Eddy current testing in the field of component testing covers a frequency range of up to 10 MHz and is used to test metals for surface defects. A wide variety of differential measurement coils are normally used for this. Standard sensors, as well as customized adaptations, are utilized. Our Eddy Current technology is recommended for the detection of close to surface defects in diverse orientations employing standard and specially designed testing probes, whereas, our magnetic induction technology is tailored for material structure testing, grade verification, and sorting according to physical and mechanical properties of components using standard and custom-made test coils. Our product portfolio includes product families of STATOGRAPH for surface crack detection, MAGNATESET for material testing, grade verification, and sorting, ZMAG for demagnetization, STATOVISION for crack detection of components with recurring patterns, and KOERZIMAT for material structure testing.

X-ray & Computer Tomography: Our product portfolio includes X-ray systems for installation in radiological inspection envelopes, universal X-ray inspection systems on the basis of fully shielded devices, as well as solutions specific to individual customers. Whether in manual, semi, or fully automated operation, our inspection systems are ideal for deployment in research and development and can be integrated into any production process. Moreover, our CT technology provides a three-dimensional insight into inspection items thus enabling the analysis of inner structures, dimensional measurement tasks in metrology applications, or actual-to-nominal comparisons to CAD data, to name a few. Besides delivering a more precise inspection evaluation (when compared with radiography), computed tomography also provides valuable information about the production process. Above and beyond such advantages, our microfocus systems permit highly detailed views into the most intricate structures and tiniest components. Our adioscopic and CT inspection of internal automotive components, namely, engine block, head cylinder, manifolds, steering parts, aluminum wheels and pumps.

Our global partners offer versatile products to our respected clients to achieve the balance between efficiency, performance and feasibility simultaneously for every operation. In addition, we offer turnkey Test system solutions for automotive and components, tools manufacturing, fasteners and connectors, forging and medical industries, including the automation components and equipment to provide assurance for the final quality of your products and comply with mandated regulations, standards and protocols.